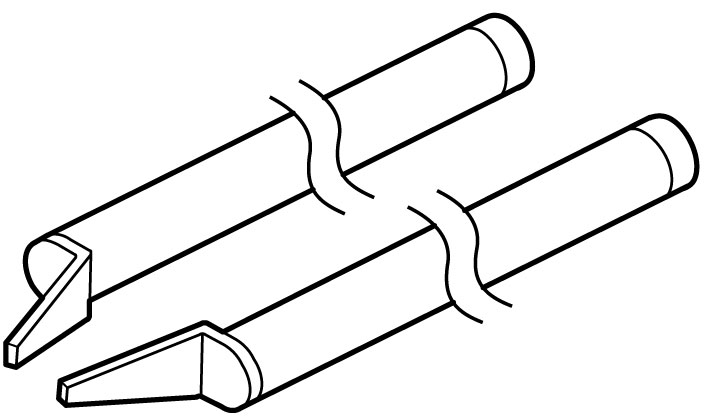

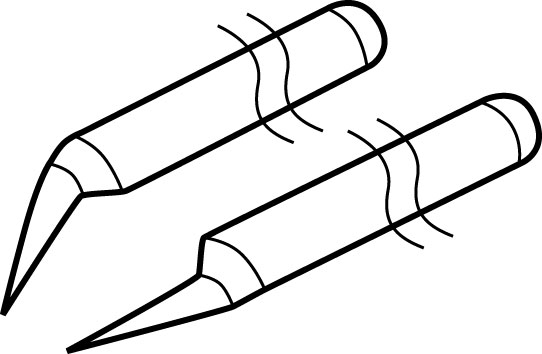

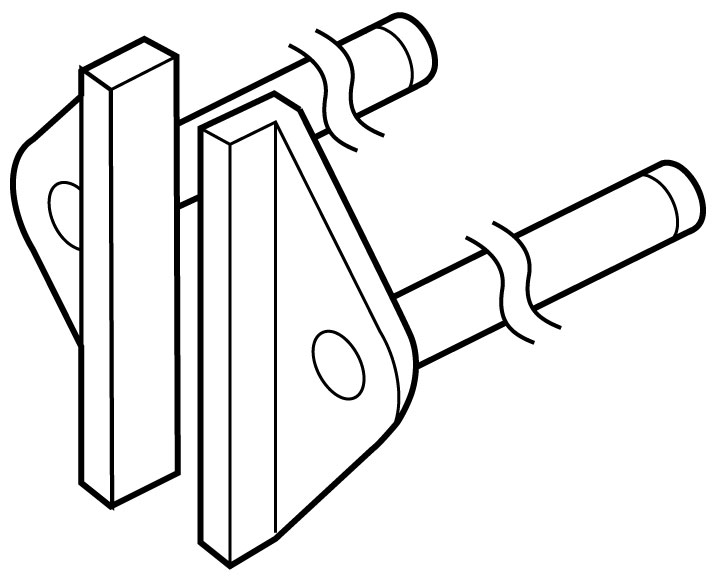

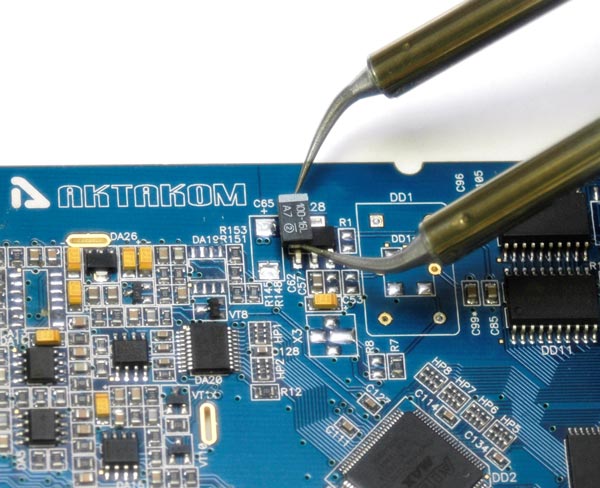

AKTAKOM ASE-1209 Soldering Tweezers (analog of 989ESD) is designed to be used with ASE-1107 soldering station for SMD component removal.

Features

- ESD safe design.

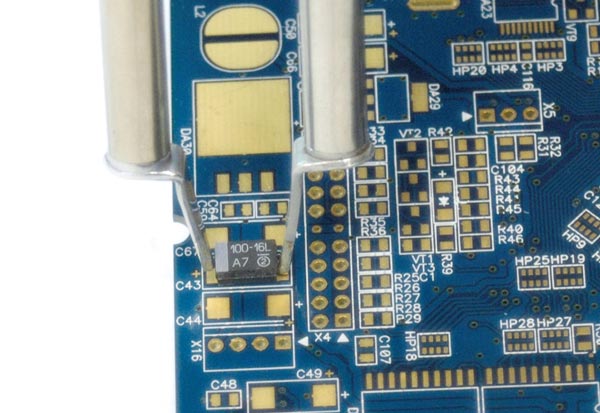

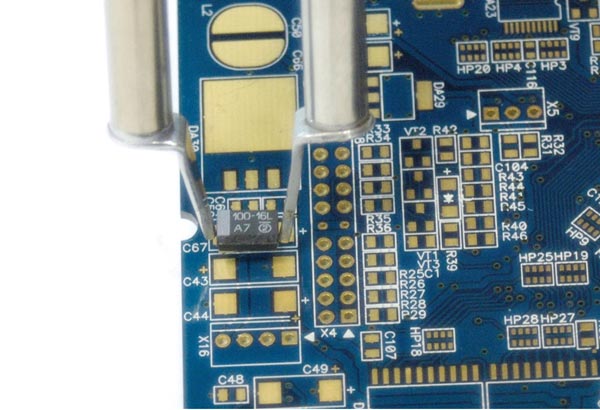

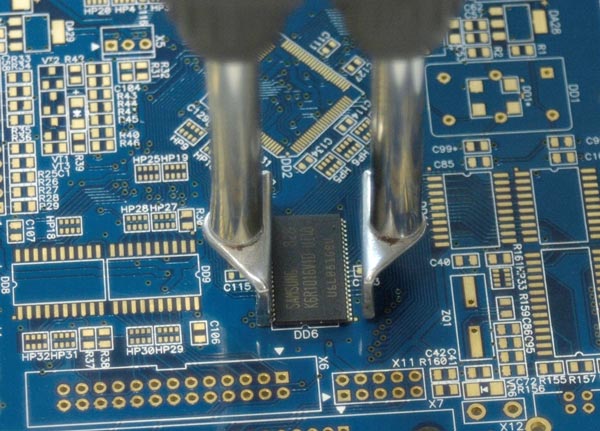

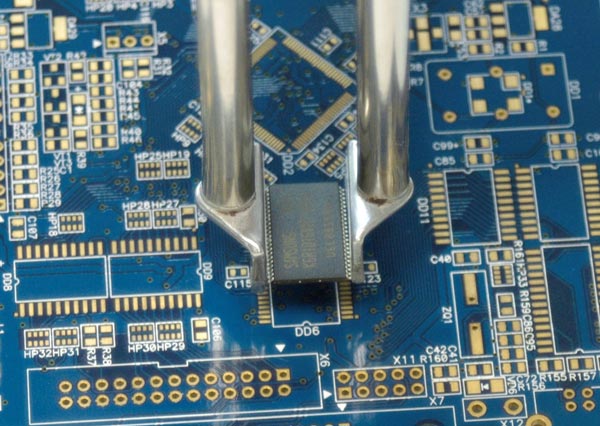

- Twin-tube heating comes into contact with the components directly without affecting adjacent components.

- Especially suitable for rework on component-densely-mounted circuit board.

- Suitable for mounting on several types of soldering stations.

- Can remove flake resistor and condenser and SOP elements safely.

Specifications

- Power: 24V AC

- Power Consumption: 25W*2

- Heating Element: Ceramic Heater

- Tip to grounded resistance: under 2Ω

- Tip to grounded Potential: under 2 mV

- Max temperature: 400°C (752°F)

Standard accessories

- Soldering Tweezers with A-1389 tip

- Soldering Tweezers holder

- Tip cleaning sponge (in the base)

- Heat-resistant grip for tip changing

- User manual

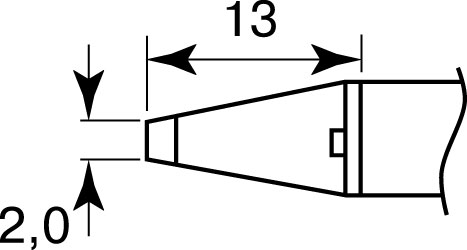

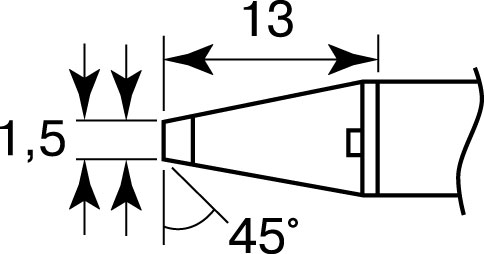

Optional Tips for ASE-1209

|

Size A (B) x Length, mm

|

A

|

Length

|

Model

|

Type

|

|

CHIP

|

|

|

1,0

|

13,0

|

A-1379

|

CHIP 1L

|

|

2,0

|

13,0

|

A-1378

|

CHIP 2L

|

|

1,5 (0,5)

|

13,0

|

A-1388

|

CHIP 0.5C

|

|

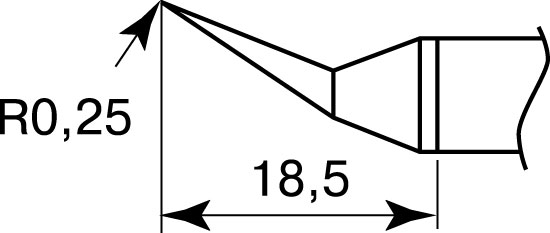

R 0,25

|

18,5

|

A-1389

|

CHIP 0.51

|

|

SOP

|

|

|

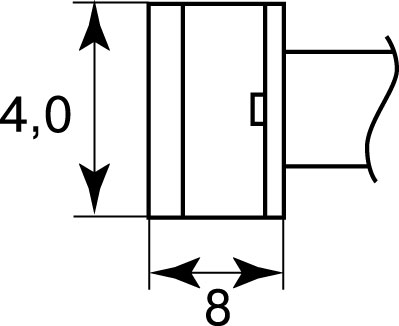

4,0

|

8,0

|

A-1390

|

SOP 4L

|

|

6,0

|

8,0

|

A-1391

|

SOP 6L

|

|

8,0

|

8,0

|

A-1380

|

SOP 8L

|

|

10,0

|

8,0

|

A-1381

|

SOP 10L

|

|

13,0

|

8,0

|

A-1382

|

SOP 13L

|

|

15,0

|

8,0

|

A-1392

|

SOP 15L

|

|

18,0

|

8,0

|

A-1383

|

SOP 18L

|

|

20,0

|

8,0

|

A-1384

|

SOP 20L

|

|

25,0

|

8,0

|

A-1385

|

SOP 25L

|

Safety instructions

Take care of yourself!

- Please read user manual carefully before using the instrument.

- Do not use the device if there is visible damage.

- Repair and maintenance of the device can be done only by a qualified specialist of the service center.

- Before connecting the instrument to the electrical network, observe all known precautions, and make sure that the grounding system is to avoid electric shock.

- Use only those accessories that are intended for use with this device.

- While working, do not touch the metal parts near the tip of the soldering iron.

- After completion of the work, it is necessary to install the soldering gun in the regular holder of the soldering gun.

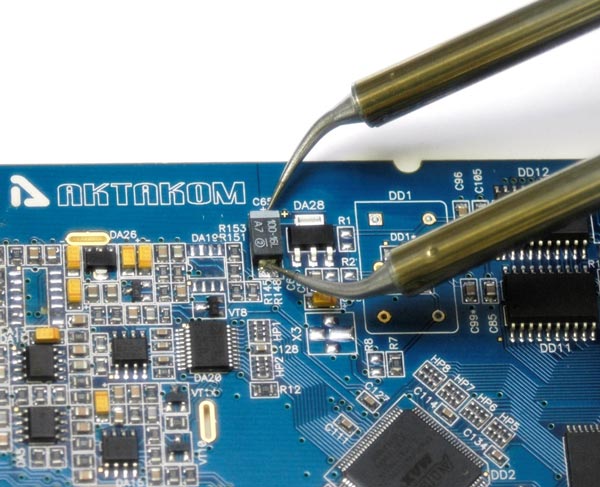

SMD components removal with ASE-1209 Soldering Tweezers

Frequently Asked Questions

How to set the temperature when operating ASE-1209?

How to replace the tip when operating ASE-1209?

How to set the temperature when operating ASE-1209?

|

When working with AKTAKOM ASE-1209 never set the temperature to any value over 400°C (752°F). Doing so may damage the station. Set the temperature according to the type of the work to be done.

Apply solder or flux

- If there is insufficient solder on the PCB, or the soldered area is too small, apply solder or flax to the PCB. Solder may also be applied to the tip.

- Melt the solder.

- Place the tip on the soldered part and melt the solder, confirm that the solder is fully melt.

- Remove the component.

- After confirming that the solder is fully melted, lightly squeeze the TWEEZER to grasp the component and lift to remove the component.

CAUTION! The high temperature of the tip may damage the PCB and put off the circuit diagram. Set the temperature at 300°C (572°F) and the tip temperature can be improved slowly with the work condition. When operating use the temperature as low as possible to prevent the sensitive component from damage and stop the tip character from decreasing.

Up

|

How to replace the tip when operating ASE-1209?

|

CAUTION! When working with AKTAKOM ASE-1209 be sure to turn off the power switch before replacing the tip. Loose the nipple by turning it counterclockwise. It is not necessary to pull it out completely.

- Insert the new tip as far as it will go, and adjust it so that it is parallel to the other tip.

- Tighten nipple to fix the tip in place.

- The tip temperature may vary according to the shape of the tip, you'd better calibrate it with soldering tester.

Up

|

LED Repair Tutorial Part 4

How to fix LED light fixture using AKTAKOM AM-1060 DMM, ASE-1209 Soldering Tweezers and APS-7306 Power Supply

ASE-1107 Soldering Station with Optional Hot Tweezers

Caracteristicas

1. Diseño seguro de ESD.

2. El calentamiento de dos tubos entra en contacto con los componentes directamente sin afectar los componentes adyacentes.

3. Especialmente adecuado para retrabajo en placa de circuito de componentes densamente montada.

4. Adecuado para montar en varios tipos de estaciones de soldadura.

5. Puede retirar la resistencia de escamas y el condensador y los elementos SOP de forma segura.

Back to the section

|

|