| www.tmatlantic.com

Test & Soldering Equipment On-line Store |

|

D.E.V.I.C.E. (Wiki)Calculators Services |

|||||

Filter by first letter

|

Soldering iron tips

At the end of most soldering irons is an interchangeable part known as a soldering tip. There are many variations of this tip and they come in a wide variety of shapes and sizes. Each tip is used for a specific purpose and offers a distinct advantage over another. The most common tips you will use in electronics projects are the conical tip and the chisel tip.

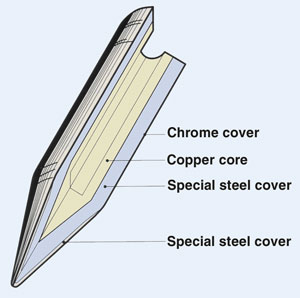

Soldering tips are made of oxygen-free copper with the steel center and nickel-chromic external covering, the correct use secures a long service life. The long exploitation term of the tips is gained due to their multilayer structure in which the external layer (chrome) is protective, internal (copper) is responsible for heat conductivity, intermediate (steel) - for durability and long operating life. And a working part (tin) - for good solder wettability.

Multilayered soldering tips don’t need any sharpening.

Unreasonable high temperature shortens service life. Use the minimal acceptable temperature, if possible. |

Site mapPrivacy policyTerms of Use & Store PoliciesHow to BuyShippingPayment

|

.jpg)