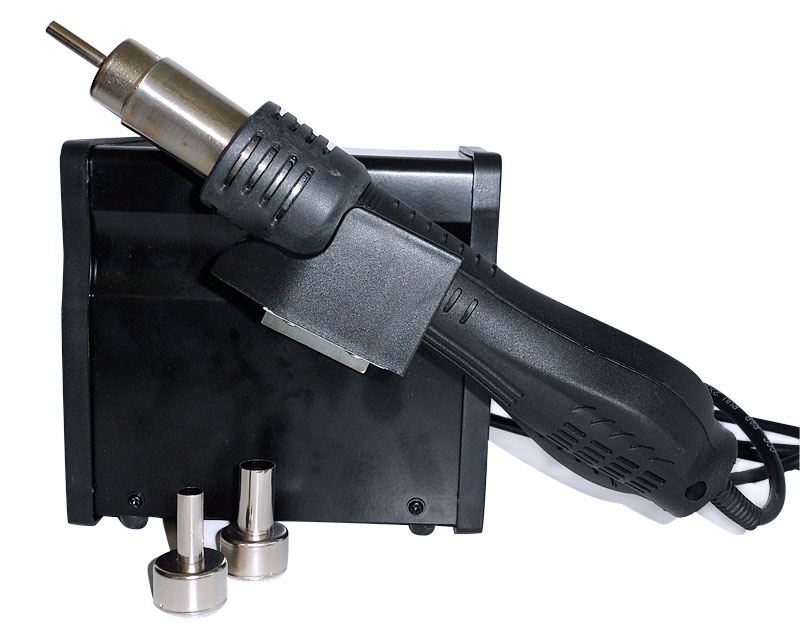

AKTAKOM ASE-4508 is a temperature controlled SMD rework station with digital indication and 700W power.

ASE-4508 rework station provides the air flow heating from 212 up to 842°F (100 up to 450°C) and the maximal air flow may achieve 120 l/min. The station is equipped with a low noise brushless fan.

One of the main features of AKTAKOM ASE-4508 SMD rework station is the wide range of replaceable nozzles which structural design is compatible with all types and dimensions of housings used for present microcircuits: QFP, SOP, PLCC and BGA. The material used for these nozzles production is stainless steel with strictly precise dimensions. Such configuration allows moving hot air flow directly to the certain microcircuit area.

AKTAKOM ASE-4508 SMD rework station is ESD-safe. This is an important requirement that should be met since the absence of antistatic protection may cause the damage of valuable electronic components with electro static discharge.

ASE-4508 rework station (analog of AT858D+) is designed for various application spheres including: average and large service centers; repair of equipment for mobile communication and radio stations; repair of handheld technologies and motherboards; repair of local network equipment and net nodes.

This rework station is rather compact and occupies a minimal space that will help you to organize a high performance work area.

Features

- LED display

- High power: 700W

- Quick temperature rising

- High and stable temperature, not affected by the air volume to achieve the lead-free unsoldering

- The air flow velocity can be easily regulated

- The handle has a special magnetic sensor, the hot air gun starts blowing only when you take it out from the holder

- There is no automatic cooling function that can extend the lifespan of the heating element and protect the rework station.

- Low noise brushless fan

- Safe and reliable

Specifications

- Input voltage: 110VAC

- Power: 700W

- Low noise brushless fan

- Noise: <45dB

- Maximal air flow: 120l/min

- Temperature range: 212…842°F / 100…450°C

- LED display

- Dimensions: 5.9x3.9x6in / 151x100x153mm

- Weight: 3.3lb /1.5kg

Warning

- Before using the rework station you must follow the measures in order not to get an electric shock, damages or fire, etc.

- Use the original parts or accessories only.

- This rework station can be repaired by the qualified specialist only.

- Be careful since you operate with high temperature. Don't use it near flammable and explosive gas and objects. Don't touch the heating element.

- Do not leave the rework station operating on its own.

- Do not install the nozzle until the heating pipe and nozzle are cooled down.

- After using the rework station remember to cool t down. You should put the handle on the holder. After the station enters the waiting mode you can take the power off.

- If you don't use it for a long time put the connector plug off.

Included accessories

- Iron holder

- Hot air gun nozzles

- Power cord

- User manual

Safety instructions

Take care of yourself!

- Please read user manual carefully before using the instrument.

- Do not use the device if there is visible damage.

- Repair and maintenance of the device can be done only by a qualified specialist of the service center.

- Before connecting the instrument to the electrical network, observe all known precautions, and make sure that the grounding system is to avoid electric shock.

- Use only those accessories that are intended for use with this device.

- While working, do not touch the metal parts near the tip of the soldering iron.

- After completion of the work, it is necessary to install the soldering gun in the regular holder of the soldering gun.

Operation instruction

Installation

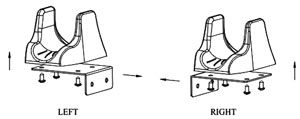

When the new machine is operatedfor the first time, you must install the handle shelf; the picture is as follows.

- According to personal habits, you can screw the four screws tightly.

- According to your need, remove the two screws of the fixed handle shelf on the right or on the left.

- Put the two installation holes of the handle shelf in the fixed screw holes, and then screw the two removed screws tightly.

- Put the components of the handleon the handle shelf and check if it is suitable.

Operation

- Place the rework station, and put the handle on the handle shelf.

- Connect the power cord, fix the nozzle which you need. (Set the air capacity max.)

- Switch the power on, set the temperature which you need.

- Hold the handle, the unit will heat normally. The unit will operate normally after the temperature is stable.

- After operating you must put the handle on the handle shelf, now the unit will stop heating automatically, and be on stand by state.

- Disconnect the power if you don't use the unit for a long time.

CAUTION! CAUTION!

If you can finish your work at a lower temperature and larger airflow, this can make the life span of the heating elements longer and make the IC chip safer.

Temperature Setting

Hot Air Rework Station of LED-based Instruction

Rotate temperature control knob to the desired location of the temperature scale line.

Hot Air Rework Station of LED Microcomputer Digital Display

- When connecting the power, press the connected keys; then the setted temperature will appear on the temperature display window.

- Press the key that is upward; then the setted temperature will rise by 1, which will appear on the display window. Press the key that is downward; then the setted temperature will fall by If the two keys are pressed successively, the temperature will rise or fall rapidly. If you release the pressed keys, the setted temperature will appear for two seconds on the display window and then the actual temperature will appear.

Note: Symbol Description

- Display “SLP”, means the outlet temperature is lower than 100 and the rework station enters the waiting mode. The handle should be put on the handle shelf.

- Display “S-E”, means there is something wrong with the sensor of the rework station. The heating elements should be changed. (heating elements and components of the sensor)

- When operating, the display temperature “H-E”, means that the temperature will not rise and the heating elements of the rework station may be damaged; the heating elements should be changed. (heating elements and components of the sensor)

Operation Instructions

- There may be very high temperature in the outlet or near it. Be careful in order not to get hurt.

- The heating handle must be put on the handle shelf. Don't put it on the table or other places.

- Keep the blowing way unblocked.

- After using, make sure the unit cool down, put it in a safe place. After turn the power off, the unit will automatically blow cool air for a short time. Don't disconnect the plug during this cooling process, it will power off automatically about one minute later.

- When operating, the distance between the outlet and the object should be at least 2mm on the basis of the outlet.

- According to the requirements of work, choose the suitable nozzle, for different nozzles are a little different in temperature

Replacement Of The Heating Element

- Replace the heating element after they are cool.

- Remove screws of the handle.

- Remove the fan, and disconnect the connecting wire of the heating element, pay attention to the position for the connecting wire.

- Take out the heating element and the mica paper from the steel tube, and do not break the mica paper.

- Use the mica paper to pack up the heating element, insert it in the steel tube, and the installation of the heating element should be on the designated position, and do not let it touch the ground wire.

- Connect the connecting wire of the heating element according to the original position.

- Install the handle and screw down the screws.

CAUTION! CAUTION!

- When changing the heating element, don't damage the grounding wire of the steel tube.

- When changing, don't damage the connecting wire of the punp.

- When you install the handle shells back, the fixed pole of the handle shells must be in the fixed hole of the steel tube.

La estacion de soldar ASE-4508 con tobera de aire caliente permite un fácil montaje y remoción de componentes SMD como QFP, BGA y SQL.

La Estación de Soldadura con Pistola de Aire Caliente ASE-4508 tiene un sin fin de prestaciones. La cubierta externa utiliza un material de aleación y de primer nivel de electricidad estática de pulverización, a prueba de humedad, anti-envejecimiento. La cantidad del aire es ajustble, control de la temperatura regulable, adatable para la realización de múltiples funciones. El sistema está equipado con la función automática de viento frío para alargar la vida útil del elemento de calefacción y proteger la pistola de aire caliente. Multiples funciones de sistema, así como alertar un mal funcionamiento.

Caracteristicas

- Regulación de sensores, de cruce por cero de control de temperatura del microprocesador; pantalla LED de alta potencia, rápido aumento de la temperatura, la temperatura alta y estable no se ve afectada por la cantidad de aire para lograr el objetivo de desoldar sin plomo

- La cantidad de flujo de aire puede ser modulada, el flujo de aire es grande y suave, conveniente para modular la temperatura, es el tipo adecuado para muchos propósitos.

- Hay un interruptor en el mango conductor, solo de sostener el mango el sistema puede entrar en el modo de trabajo con rapidez, mientras que si el mango se coloca en el estante o base pasa al estado de espera. Esto lo hace muy fácil de operar.

- No existe una función de refrigeración automático, que puede ampliar la vida útil del elemento de calefacción y proteger a la estación de con tobera de aire caliente.

- Carcasa de plástico, tipo gabinete, guapa a la vista y que ocupa poco espacio.

- Se adopta el ventilador sin escobillas, que tiene una larga vida útil y poco ruido.

- El soplado de componentes plásticos no les deforma. Como timbres y la interfaz externa del teléfono móvil.

- El soplado de cajas electricas de blindaje no lo hará cambiar de color.

- El soplado de PCB no le hara ampollas o deformaciones con burbujas.

- La remocion con BAG-IC, le ayudara a mantener los pines intactos. Este modo de operar es mucho más seguro y confiable.

Parametros Técnicos

- Voltaje: 110VAC

- Potencia: 700W

- Flujo de gas: 120l/min (max)

- Tipo de bomba: Ventilador sin escobillas

- Rango de Temperatura: 212-842°F / 100-450°C

- Nivel de Ruido:<45dB

- Pantalla: LED

- Dimensiones: 5,9x3,9x6in/151x100x153mm

- Peso: 3.3in/1.5kg

Back to the section

|

|